Trung tâm gia công dọcBrema

Vektor 15 - 13

Trung tâm gia công dọc

Brema

Vektor 15 - 13

Năm sản xuất

2019

Tình trạng

Đã qua sử dụng

Vị trí

Sesto Calende

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

- Tên máy:

- Trung tâm gia công dọc

- Nhà sản xuất:

- Brema

- Mô hình:

- Vektor 15 - 13

- Năm sản xuất:

- 2019

- Tình trạng:

- đã qua sử dụng

Giá & Vị trí

- Vị trí:

- Sesto Calende, Italy

Gọi điện

Chi tiết về đề nghị

- ID tin đăng:

- A10298021

- Số tham chiếu:

- MHF003

- Cập nhật:

- lần cuối vào ngày 18.10.2024

Mô tả

Highly flexible vertical machining center for milling, drilling and cutting. The BREMA patent for processing

vertically, allows this series of machines to be the most flexible and productive machine par excellence

to a very high quality level. Furthermore, the automatic return / rotation system of the panel makes it

fully automated.

Possibility of working in height up to 1300 mm, working on all 6 sides of the panel.

Working dimensions:

* length 300 - 2500 mm

* height 60 - 1300 mm

* thickness 10 - 80 mm

* max weight 50 kg

Machine programming and control system with PC - TPA Albatros software.

Programming editor with a high-level software interface allows you to program the machine easily and

intuitively and also allows:

* linear, circular and helical interpolation

* double zero reading

* mirror program management

* optimizer for revolver tool diameter

* optimizer for independent spindle diameter

* DXF file conversion (geometric conversion)

* import of work lists in ASCII format

* extra key for programming from the office

* gun barcode reader

* 17” LCD monitor

* Windows 7 professional operating system

Panel introduction and handling by means of motorized vertical transfer with rollers and rubber-coated pressers for sealing

of the panel during the workings, with a motorized carpet length of 2000 mm, with speed regulation

Fjdpfx Ael Ikzgja Nefu

electronically adjustable with converter. The photocells and the NC program guarantee the introduction of one or more

panels in sequence using selector.

Panel height reading system consisting of an independent axis able to read the panel height

before getting into the car.

Size reading tolerance +\- 0.15 mm. In case the tolerance is exceeded a message will inform

the operator and the machine will stop the operation in progress.

Panel thickness reading system using a mechanical feeler

Horizontal vice - M.O. axis which allows the thickness of the workpiece to be established from the program.

Vertical vice - M.V. axis which allows the program to establish the height dimension of the piece being processed.

Chain - X axis - patent double section with laser photocells able to read the reference zero of the

panel before carrying out the work.

The double section allows you to carry out machining on the lower side of the panel thus having the possibility of

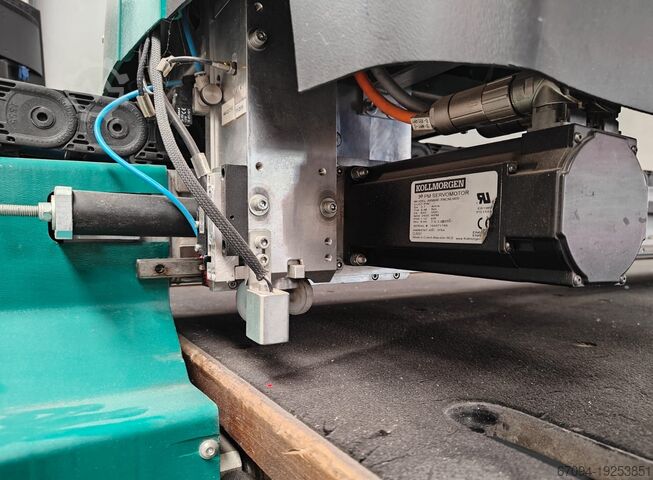

work the panel on 6 sides. Brushless motors with programmable speed regulation by NC.

Drilling unit with independent spindles 7 + 17 x 32 mm

24 independent spindles with 32 mm pitch arranged as follows:

* 7 spindles aligned in X axis

* 17 spindles aligned in Y axis

Unit driven by a high-frequency motor that allows the rotation change of the spindles up to 7000 RPM

The Brushless motor allows drilling depth control and forward speed control.

Upper revolver milling group with 10 positions and tool change controlled by NC.

11 KW motor with direct transmission of movement to the tool up to 18000 RPM. The rotation of the revolver generated by

controlled axis with Brushless motor allows quick tool change.

10 aggregate heads included in the revolver

Automatic lubrication

180° panel translation and rotation system

Movement and rotation system of the panel arriving from the machine which allows unloading or rotation

of the panel and the return to the machine for machining on both surf

vertically, allows this series of machines to be the most flexible and productive machine par excellence

to a very high quality level. Furthermore, the automatic return / rotation system of the panel makes it

fully automated.

Possibility of working in height up to 1300 mm, working on all 6 sides of the panel.

Working dimensions:

* length 300 - 2500 mm

* height 60 - 1300 mm

* thickness 10 - 80 mm

* max weight 50 kg

Machine programming and control system with PC - TPA Albatros software.

Programming editor with a high-level software interface allows you to program the machine easily and

intuitively and also allows:

* linear, circular and helical interpolation

* double zero reading

* mirror program management

* optimizer for revolver tool diameter

* optimizer for independent spindle diameter

* DXF file conversion (geometric conversion)

* import of work lists in ASCII format

* extra key for programming from the office

* gun barcode reader

* 17” LCD monitor

* Windows 7 professional operating system

Panel introduction and handling by means of motorized vertical transfer with rollers and rubber-coated pressers for sealing

of the panel during the workings, with a motorized carpet length of 2000 mm, with speed regulation

Fjdpfx Ael Ikzgja Nefu

electronically adjustable with converter. The photocells and the NC program guarantee the introduction of one or more

panels in sequence using selector.

Panel height reading system consisting of an independent axis able to read the panel height

before getting into the car.

Size reading tolerance +\- 0.15 mm. In case the tolerance is exceeded a message will inform

the operator and the machine will stop the operation in progress.

Panel thickness reading system using a mechanical feeler

Horizontal vice - M.O. axis which allows the thickness of the workpiece to be established from the program.

Vertical vice - M.V. axis which allows the program to establish the height dimension of the piece being processed.

Chain - X axis - patent double section with laser photocells able to read the reference zero of the

panel before carrying out the work.

The double section allows you to carry out machining on the lower side of the panel thus having the possibility of

work the panel on 6 sides. Brushless motors with programmable speed regulation by NC.

Drilling unit with independent spindles 7 + 17 x 32 mm

24 independent spindles with 32 mm pitch arranged as follows:

* 7 spindles aligned in X axis

* 17 spindles aligned in Y axis

Unit driven by a high-frequency motor that allows the rotation change of the spindles up to 7000 RPM

The Brushless motor allows drilling depth control and forward speed control.

Upper revolver milling group with 10 positions and tool change controlled by NC.

11 KW motor with direct transmission of movement to the tool up to 18000 RPM. The rotation of the revolver generated by

controlled axis with Brushless motor allows quick tool change.

10 aggregate heads included in the revolver

Automatic lubrication

180° panel translation and rotation system

Movement and rotation system of the panel arriving from the machine which allows unloading or rotation

of the panel and the return to the machine for machining on both surf

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Đã đăng ký từ: 2017

Gửi yêu cầu

Điện thoại & Fax

+39 0331 ... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Đấu giá

Kết thúc trong

d

h

min

s

Đấu giá đã kết thúc

Lombardia

Lombardia

9.632 km

Trung tâm gia công qua dòng

BREMAVEKTOR 15-13

BREMAVEKTOR 15-13

Quảng cáo nhỏ

Maasmechelen

Maasmechelen

9.662 km

Bàn cắt kính

Bottero353BKM-J

Bottero353BKM-J

Quảng cáo nhỏ

Lennestadt

Lennestadt

9.506 km

Trung tâm gia công liên tục

BRE.MAVEKTOR 15-13 CNC

BRE.MAVEKTOR 15-13 CNC

Quảng cáo nhỏ

Krefeld

Krefeld

9.589 km

Băng tải kính thiên văn băng tải đai

BuddeTGF03

BuddeTGF03

Quảng cáo nhỏ

Zamość

Zamość

8.467 km

Máy phay sao chép

RotoxZOR 941

RotoxZOR 941

Quảng cáo nhỏ

Sliven

Sliven

8.311 km

Tối ưu hóa đường chéo

WEINIGOpticut 200 Elite

WEINIGOpticut 200 Elite

Quảng cáo nhỏ

HETEREN

HETEREN

9.625 km

Xe cẩu

Mercedes-BenzArocs 3251 AROCS 3251 8x2 FASSI F820RA.2.28

Mercedes-BenzArocs 3251 AROCS 3251 8x2 FASSI F820RA.2.28

Quảng cáo nhỏ

Maulbronn

Maulbronn

9.518 km

Trung tâm gia công thanh

elumatecSBZ 150

elumatecSBZ 150

Quảng cáo nhỏ

Alberschwende

Alberschwende

9.491 km

Máy bào và đá tảng

WEINIGPowermat 1500

WEINIGPowermat 1500

Quảng cáo nhỏ

Lleida

Lleida

10.393 km

Cần cẩu nhẹ 500 kg

ABUS500kg 10 x 7 m

ABUS500kg 10 x 7 m

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi