Xưởng cưa hoàn chỉnh (cố định)MADREW

AE-400

Xưởng cưa hoàn chỉnh (cố định)

MADREW

AE-400

Tình trạng

Mới

Vị trí

Szczecinek

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

Giá & Vị trí

- Vị trí:

- Harcerska 1, 78-400 Szczecinek, Polska

Gọi điện

Chi tiết về đề nghị

- ID tin đăng:

- A12195374

- Cập nhật:

- lần cuối vào ngày 12.11.2024

Mô tả

The AE-400 SERVO edger is designed for longitudinal trimming and slitting of side boards fed to the machine at high speeds (100-400m/minute).

The machine works directly with conveyors feeding and receiving boards in automatic mode.

The machine is equipped with a board scanner from above and below.

The maximum instantaneous efficiency of the edger up to 55 boards/min can be obtained by cutting a 2.5 m board to the same width without changing the spacing of the saw blades. Each adjustment of the edger node devices to the width of the board causes a change in performance. The average productivity of the machine, depending on the work configuration, ranges from 35-48 boards/min.

technical dance

No. Parameter Value

1. Saw spindle drive motor power. 55 kW

2. The number of revolutions of the saw spindle. 3550 rpm

3. Diameters of used saws. 400mm

4. Maximum cutting height. 50mm

5. Number of saw blades used. 2 to 3 pcs. (2 floating saws)

6. Minimum board length. 2000mm

7. Maximum raw material length. 6200mm

8. Maximum number of boards after cutting 1 board: 2 pcs.

9. Feed: 100- 400m/min

Cutting for 1 board - with two saws (2 floating saws):

1. Minimum saw spacing (board width after cutting) 75 mm

2. Maximum spacing of extreme saw blades (board width after cutting) 300 mm

Iedpfx Aaenygvrezstb

Cutting into 2 boards - with three saws (2 floating saws),

1. Spacing the saws on the fixed coupler

(board width after cutting) 50-100mm

2. Spacing between floating saws

(board width after cutting) 50-100mm

3. Cutting into 2 boards minimum 2 x 50mm

4. Cutting into 2 boards maximum 2 x 100mm

Other machine configurations are possible on request.

We also produce other sawmill lines: log sorting plants, board sorting plants, board stackers, conveyors.

The machine works directly with conveyors feeding and receiving boards in automatic mode.

The machine is equipped with a board scanner from above and below.

The maximum instantaneous efficiency of the edger up to 55 boards/min can be obtained by cutting a 2.5 m board to the same width without changing the spacing of the saw blades. Each adjustment of the edger node devices to the width of the board causes a change in performance. The average productivity of the machine, depending on the work configuration, ranges from 35-48 boards/min.

technical dance

No. Parameter Value

1. Saw spindle drive motor power. 55 kW

2. The number of revolutions of the saw spindle. 3550 rpm

3. Diameters of used saws. 400mm

4. Maximum cutting height. 50mm

5. Number of saw blades used. 2 to 3 pcs. (2 floating saws)

6. Minimum board length. 2000mm

7. Maximum raw material length. 6200mm

8. Maximum number of boards after cutting 1 board: 2 pcs.

9. Feed: 100- 400m/min

Cutting for 1 board - with two saws (2 floating saws):

1. Minimum saw spacing (board width after cutting) 75 mm

2. Maximum spacing of extreme saw blades (board width after cutting) 300 mm

Iedpfx Aaenygvrezstb

Cutting into 2 boards - with three saws (2 floating saws),

1. Spacing the saws on the fixed coupler

(board width after cutting) 50-100mm

2. Spacing between floating saws

(board width after cutting) 50-100mm

3. Cutting into 2 boards minimum 2 x 50mm

4. Cutting into 2 boards maximum 2 x 100mm

Other machine configurations are possible on request.

We also produce other sawmill lines: log sorting plants, board sorting plants, board stackers, conveyors.

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Đã đăng ký từ: 2023

Gửi yêu cầu

Điện thoại & Fax

+48 600 2... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Quảng cáo nhỏ

Geiselwind

Geiselwind

9.378 km

Cưa đóng gói Vario Cut

HOLTECVario Cut

HOLTECVario Cut

Quảng cáo nhỏ

Warburg

Warburg

9.416 km

Máy hủy tài liệu hai trục

Arjes / EggersmannImpaktor 250 EVO II

Arjes / EggersmannImpaktor 250 EVO II

Quảng cáo nhỏ

Grafenwöhr

Grafenwöhr

9.275 km

Máy hủy trục đơn

LINDNER RecyclingtechJupiter 2200

LINDNER RecyclingtechJupiter 2200

Quảng cáo nhỏ

Seva

Seva

10.258 km

Máy sấy trống

SAFEM

SAFEM

Quảng cáo nhỏ

Jonava

Jonava

8.359 km

20-29-556 rộng vành đai với máy chà nhám

WOODLAND MACHINERYR-R-RP1300

WOODLAND MACHINERYR-R-RP1300

Quảng cáo nhỏ

Zabok

Zabok

9.081 km

SỰ ĐĂNG KÝ

Quảng cáo nhỏ

Strenči

Strenči

8.261 km

Cưa đa lưỡi

A.CostaLeopard

A.CostaLeopard

Quảng cáo nhỏ

Neckartailfingen

Neckartailfingen

9.497 km

Máy ép kiện với hệ thống khử bụi

mütek

mütek

Quảng cáo nhỏ

Rödermark

Rödermark

9.485 km

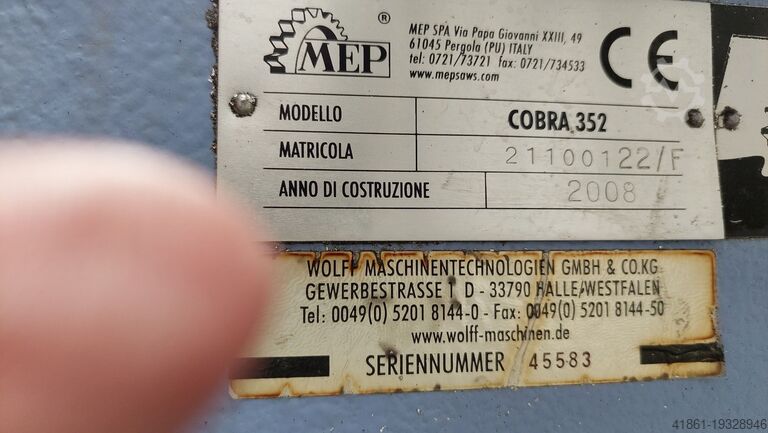

Cưa cắt góc bằng nhôm

MEPCobra 352

MEPCobra 352

Quảng cáo nhỏ

Gorzów Wielkopolski

Gorzów Wielkopolski

8.978 km

Bộ chia log

OptimatTitanium CLS30-E 500

OptimatTitanium CLS30-E 500

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi