Thân máy cắt ZERMA GST250/450 thân rỗngZERMA

GST 250/450

Thân máy cắt ZERMA GST250/450 thân rỗng

ZERMA

GST 250/450

EXW VB chưa bao gồm thuế GTGT

18.100 €

Năm sản xuất

2025

Tình trạng

Mới

Vị trí

Buchholz in der Nordheide

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

- Nhà sản xuất:

- ZERMA

- Mô hình:

- GST 250/450

- Năm sản xuất:

- 2025

- Tình trạng:

- mới

- Tính năng hoạt động:

- hoạt động hoàn toàn

- Giờ vận hành:

- 1 h

Giá & Vị trí

EXW VB chưa bao gồm thuế GTGT

18.100 €

- Vị trí:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

Gọi điện

Chi tiết về đề nghị

- ID tin đăng:

- A17133937

- Cập nhật:

- lần cuối vào ngày 03.05.2025

Mô tả

Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

Ltsdjum Rnvepfx Ac Dea

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

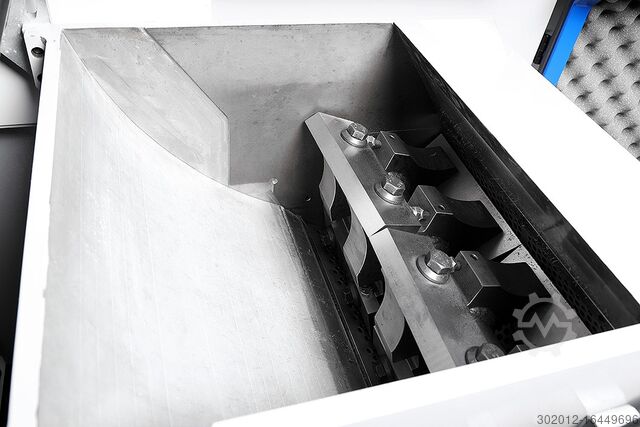

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

98T8Mrx

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Tin đăng này được dịch tự động. Có thể có lỗi dịch thuật.

Shredding of large-volume blow-molded parts as well as start and end pieces

Ltsdjum Rnvepfx Ac Dea

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

98T8Mrx

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Tin đăng này được dịch tự động. Có thể có lỗi dịch thuật.

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Đã đăng ký từ: 2023

Gửi yêu cầu

Điện thoại & Fax

+49 4181 ... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Quảng cáo nhỏ

Brahlstorf

Brahlstorf

9.244 km

Máy cắt tốc độ cao

ZERMAGST 250/450

ZERMAGST 250/450

Quảng cáo nhỏ

Zuzenhausen

Zuzenhausen

9.506 km

Nhà máy bên

ZERMAGSL 300

ZERMAGSL 300

Quảng cáo nhỏ

Buchholz in der Nordheide

Buchholz in der Nordheide

9.314 km

Máy băm nhỏ

ZermaGST 250/450

ZermaGST 250/450

Quảng cáo nhỏ

Tata

Tata

8.866 km

Máy tạo hạt

TRIA 20-15 BL-Tgranulator

TRIA 20-15 BL-Tgranulator

Quảng cáo nhỏ

Dinkelscherben

Dinkelscherben

9.410 km

Nam châm băng qua Khối từ tính Nam châm băng Fe

die magnetprofisPEM600x500x180SCH

die magnetprofisPEM600x500x180SCH

Quảng cáo nhỏ

Raitenbuch

Raitenbuch

9.353 km

Mühle Dreher S 34/52 VS có nhân

DreherDelta 34/41

DreherDelta 34/41

Quảng cáo nhỏ

Zuzenhausen

Zuzenhausen

9.506 km

Máy tạo hạt

ZERMAGS 300/400 N

ZERMAGS 300/400 N

Quảng cáo nhỏ

Đức

Đức

9.489 km

Máy cắt Wittmann MC (điều 10110)

WittmannMC 4660

WittmannMC 4660

Quảng cáo nhỏ

Brahlstorf

Brahlstorf

9.244 km

Máy cắt chạy chậm

ZERMAGSL 300/400

ZERMAGSL 300/400

Quảng cáo nhỏ

Ljubljana - Črnuče

Ljubljana - Črnuče

9.179 km

Máy tạo hạt cho phế liệu nhựa

WittmannG-max 13

WittmannG-max 13

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi