Máy chà nhám chổiDANIBRUM

DAS LDX 1000 - 6

Máy chà nhám chổi

DANIBRUM

DAS LDX 1000 - 6

Năm sản xuất

2025

Tình trạng

Mới

Vị trí

Vermești

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

- Tên máy:

- Máy chà nhám chổi

- Nhà sản xuất:

- DANIBRUM

- Mô hình:

- DAS LDX 1000 - 6

- Năm sản xuất:

- 2025

- Tình trạng:

- mới

- Tính năng hoạt động:

- hoạt động hoàn toàn

Giá & Vị trí

- Vị trí:

- Strada Combinatului, Bacău 605200, România

Gọi điện

Chi tiết về đề nghị

- ID tin đăng:

- A19072501

- Cập nhật:

- lần cuối vào ngày 05.05.2025

Mô tả

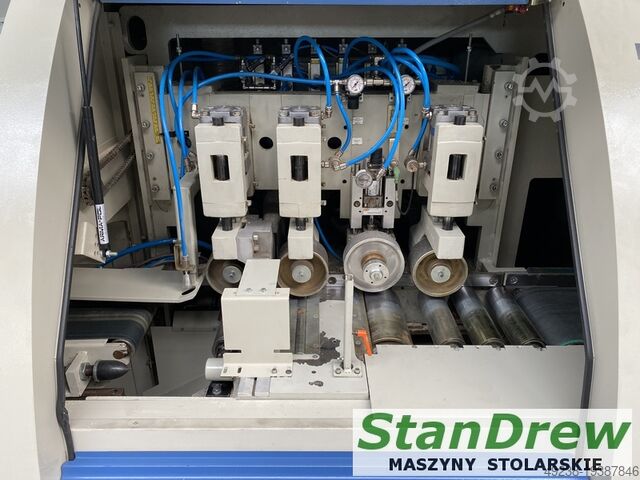

Improve the quality of your finish with the DAS LDX 1000 – 6 brush sander

The DAS LDX 1000 – 6 automatic machine is designed for precise sanding and finishing of profiled wood or MDF elements, offering excellent results even for the most demanding aesthetic requirements. It is ideal for smoothing, fine sanding and final preparation of surfaces, thanks to the versatile and robust configuration of the 6 working units.

Standard features and technical characteristics:

Multiple working units: oscillating longitudinal drums, oscillating pads, transverse drums with Ø 280 mm and width 1000 mm, equipped with 20 helically mounted brushes.

Working capacity: max. width 1000 mm, workpiece thickness max. 100 mm.

Efficient sanding: disc rotation speed between 50 – 300 RPM (adjustable via frequency inverter).

Sanding brushes: adjustable length between 20 – 70 mm, allowing detailed work on profiles with a depth of up to 8 mm.

Touchscreen control panel: Ergonomically positioned, it allows independent control of each unit. The interface is intuitive, developed by DANIBRUM engineers for fast and efficient operation.

Adherent conveyor belt: Equipped with ribbed rubber for constant advance, driven by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor and brushes for dust removal at the entrance and exit.

Professional sliding system: Based on recirculating ball bearings, it offers precise, reliable and low-maintenance movement. Lubrication is done manually.

Oscillation for sanding units: Ensures uniform finishing and prolongs the life of abrasive belts and sisal brushes.

Efficient exhaust system: Each group has dedicated exhaust ports, connected to 8 Ø 100 mm outlets, keeping the work area clean and efficient.

Fast side access: Large side openings allow easy brush changes and quick access for maintenance.

Toothed belt transmission: Ensures constant speeds, stable transmission and low noise level during operation.

Flexibility in finishing: The "fast release" system allows for quick changes of belts and brushes. The adaptable configuration is suitable for various styles and types of finishing.

The DAS LDX 1000 – 6 machine is an efficient solution for manufacturers who want superior quality in the processing of profiled wood elements, with high productivity and impeccable finishing.

Maximum working width

1000 mm

Maximum working height

100 mm

Longitudinal drum diameter (Ø)

220 mm

Longitudinal drum drive motor power - oscillating

2 x 1.5 kW

Longitudinal drum oscillation motor power

0.55 kW

Oscillating pad diameter

200 mm

Oscillating pad drive motor power

1.5 kW

Pad oscillation motor power

0.18 kW

Transverse drum diameter (Ø)

280 mm

Transverse drum drive motor power

2 x 2.2 kW

Advance motor power

1.1 kW

Redpfxjwhbtze Ab Ijp

Brush speed

max. 1000 rpm

Exhaust hood diameter (Ø)

4 x 100 mm

Overall dimensions

3300 x 1600 mm

Weight

1500 kg

Technical support available in Romanian, English or German.

Tin đăng này được dịch tự động. Có thể có lỗi dịch thuật.

The DAS LDX 1000 – 6 automatic machine is designed for precise sanding and finishing of profiled wood or MDF elements, offering excellent results even for the most demanding aesthetic requirements. It is ideal for smoothing, fine sanding and final preparation of surfaces, thanks to the versatile and robust configuration of the 6 working units.

Standard features and technical characteristics:

Multiple working units: oscillating longitudinal drums, oscillating pads, transverse drums with Ø 280 mm and width 1000 mm, equipped with 20 helically mounted brushes.

Working capacity: max. width 1000 mm, workpiece thickness max. 100 mm.

Efficient sanding: disc rotation speed between 50 – 300 RPM (adjustable via frequency inverter).

Sanding brushes: adjustable length between 20 – 70 mm, allowing detailed work on profiles with a depth of up to 8 mm.

Touchscreen control panel: Ergonomically positioned, it allows independent control of each unit. The interface is intuitive, developed by DANIBRUM engineers for fast and efficient operation.

Adherent conveyor belt: Equipped with ribbed rubber for constant advance, driven by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor and brushes for dust removal at the entrance and exit.

Professional sliding system: Based on recirculating ball bearings, it offers precise, reliable and low-maintenance movement. Lubrication is done manually.

Oscillation for sanding units: Ensures uniform finishing and prolongs the life of abrasive belts and sisal brushes.

Efficient exhaust system: Each group has dedicated exhaust ports, connected to 8 Ø 100 mm outlets, keeping the work area clean and efficient.

Fast side access: Large side openings allow easy brush changes and quick access for maintenance.

Toothed belt transmission: Ensures constant speeds, stable transmission and low noise level during operation.

Flexibility in finishing: The "fast release" system allows for quick changes of belts and brushes. The adaptable configuration is suitable for various styles and types of finishing.

The DAS LDX 1000 – 6 machine is an efficient solution for manufacturers who want superior quality in the processing of profiled wood elements, with high productivity and impeccable finishing.

Maximum working width

1000 mm

Maximum working height

100 mm

Longitudinal drum diameter (Ø)

220 mm

Longitudinal drum drive motor power - oscillating

2 x 1.5 kW

Longitudinal drum oscillation motor power

0.55 kW

Oscillating pad diameter

200 mm

Oscillating pad drive motor power

1.5 kW

Pad oscillation motor power

0.18 kW

Transverse drum diameter (Ø)

280 mm

Transverse drum drive motor power

2 x 2.2 kW

Advance motor power

1.1 kW

Redpfxjwhbtze Ab Ijp

Brush speed

max. 1000 rpm

Exhaust hood diameter (Ø)

4 x 100 mm

Overall dimensions

3300 x 1600 mm

Weight

1500 kg

Technical support available in Romanian, English or German.

Tin đăng này được dịch tự động. Có thể có lỗi dịch thuật.

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Đã đăng ký từ: 2009

Gửi yêu cầu

Điện thoại & Fax

+40 756 3... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Quảng cáo nhỏ

Strassberg

Strassberg

9.521 km

Máy làm tròn và mài cạnh

LissmacSBM-XS-300 G1E1

LissmacSBM-XS-300 G1E1

Quảng cáo nhỏ

Böblingen

Böblingen

9.513 km

Máy phay bàn

Holzkraftminimax t 45c Tischfräse

Holzkraftminimax t 45c Tischfräse

Quảng cáo nhỏ

Scerne

Scerne

9.304 km

Cưa bảng dọc

Putsch MeniconiUniver

Putsch MeniconiUniver

Quảng cáo nhỏ

Rumani

Rumani

8.386 km

Máy nesting CNC với chức năng nạp và tháo hàng

NanxingNCG3021L

NanxingNCG3021L

Quảng cáo nhỏ

Ludwigsstadt

Ludwigsstadt

9.297 km

Bàn chải deburring máy

WeberTTS-1100

WeberTTS-1100

Quảng cáo nhỏ

Egenhofen

Egenhofen

9.372 km

Máy đánh bóng, máy mài

- ItalyAdvance ROTOR 600.4 / Special 5

- ItalyAdvance ROTOR 600.4 / Special 5

Quảng cáo nhỏ

Nattheim

Nattheim

9.425 km

Sơn tường hút sương

HöckerPaint Star 3500

HöckerPaint Star 3500

Quảng cáo nhỏ

Miechucino

Miechucino

8.768 km

Máy tối ưu hóa GreCon Dimter OPTICUT 350

WEINIGDimter Opticut 350 R

WEINIGDimter Opticut 350 R

Quảng cáo nhỏ

Đức

Đức

9.517 km

Máy mài chải Fladder Gyro 300 VAC M

FladderFladder Gyro 300 VAC Ex.

FladderFladder Gyro 300 VAC Ex.

Quảng cáo nhỏ

Egenhofen

Egenhofen

9.372 km

Máy phay trục xoay

RoblandTi 120 E

RoblandTi 120 E

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi