Hệ thống láiLISEC

conveyer - positioning tables

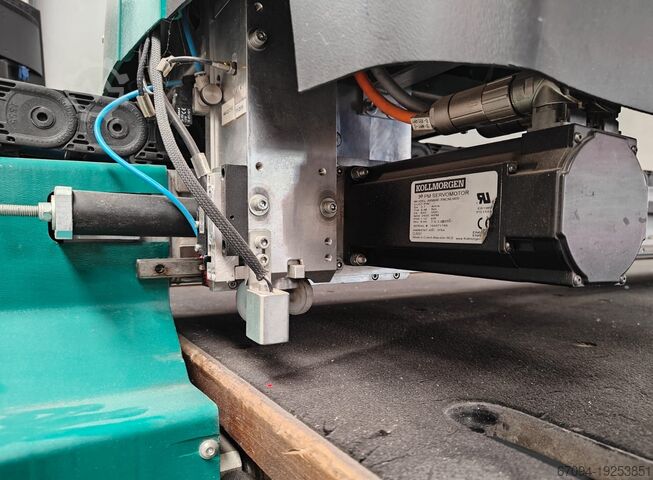

Hệ thống lái

LISEC

conveyer - positioning tables

VB chưa bao gồm thuế GTGT

15.000 €

Năm sản xuất

2019

Tình trạng

Đã qua sử dụng

Vị trí

Lleida

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

- Tên máy:

- Hệ thống lái

- Nhà sản xuất:

- LISEC

- Mô hình:

- conveyer - positioning tables

- Năm sản xuất:

- 2019

- Tình trạng:

- đã qua sử dụng

- Tính năng hoạt động:

- hoạt động hoàn toàn

Giá & Vị trí

VB chưa bao gồm thuế GTGT

15.000 €

- Vị trí:

- Lleida, Spain

Gọi điện

Chi tiết về đề nghị

- ID tin đăng:

- A18679116

- Số tham chiếu:

- S-SCP-103

- Cập nhật:

- lần cuối vào ngày 02.02.2026

Mô tả

• Rund 20 Meter lang ist die industrielle LISEC Produktionslinie, die in bis zu 350 cm Breite

LISEC Transporteinheit 33/40

Pyrosil System 500 HE (Pyrosil application for UV Ink)

LISEC Transporteinheit 33/45S

Primer Station 500 HE

LISEC Transporteinheit 33/68

LISEC Transporteinheit 33/28 mobil

Abluftanlage Vorbehandlung

LISEC Anlagensteuerung

Eine gesamte Produktionsanlage besteht aus der Reinigung, der Beflammung, dem Primer sowie den jeweiligen Transportbändern zwischen den Stationen.

• Werden nach der Reinigung auf einen mobilen Tisch abgelegt, zum Beladeband gefahren wird, wo das Glas vom Transportband der Produktionslinie übernommen wird.

und den Transport durch die Beflammung und den Primer steuert. In der Beflammungsstation wird das Glas mit einer offenen Flamme im Durchlaufverfahren beflammt. Das verbessert die Gleichmäßigkeit der Oberflächenspannung des Glases, verbrennt Rückstände oder Schmutz der beim Waschen nicht entfernt wurde und verbessert mit Silangas die Haftung des Primers.

Ein Pufferband transportiert das Glas in die Primerstation, in der aus vier Düsen in hoher Geschwindigkeit der Haftvermittler auf das Glas gesprüht wird. Dann läuft das Glas auf das lange Positionierungsband, dass einerseits als Puffer dient und gleichzeitig das Glas rechtwinklig in exakter XY-Richtung ausrichtet.

Die elektonische Steuerung der rund 20 Meter langen Produktionslinie nimmt Rücksicht auf das Format der jeweiligen Glasscheiben bei der Beflammung und beim Primen und überwacht mit Sensoren ihren Transport.

Fsdpfxev Ibmpj Aa Nefu

• LISEC production line is about 20 meters long

An entire production line consists of the cleaning, flame, primer and printing press as well as the respective conveyor belts between the stations.

• After cleaning, are placed on a mobile table, which is driven from the printer to the loading belt, where the glass is taken from the conveyor belt of the production line.

receives the print jobs from the prepress department and controls the transport through the flame and the primer. In the flame station, the glass is flame-flamed with an open flame in the continuous process. This improves the uniformity of the surface tension

LISEC Transporteinheit 33/40

Pyrosil System 500 HE (Pyrosil application for UV Ink)

LISEC Transporteinheit 33/45S

Primer Station 500 HE

LISEC Transporteinheit 33/68

LISEC Transporteinheit 33/28 mobil

Abluftanlage Vorbehandlung

LISEC Anlagensteuerung

Eine gesamte Produktionsanlage besteht aus der Reinigung, der Beflammung, dem Primer sowie den jeweiligen Transportbändern zwischen den Stationen.

• Werden nach der Reinigung auf einen mobilen Tisch abgelegt, zum Beladeband gefahren wird, wo das Glas vom Transportband der Produktionslinie übernommen wird.

und den Transport durch die Beflammung und den Primer steuert. In der Beflammungsstation wird das Glas mit einer offenen Flamme im Durchlaufverfahren beflammt. Das verbessert die Gleichmäßigkeit der Oberflächenspannung des Glases, verbrennt Rückstände oder Schmutz der beim Waschen nicht entfernt wurde und verbessert mit Silangas die Haftung des Primers.

Ein Pufferband transportiert das Glas in die Primerstation, in der aus vier Düsen in hoher Geschwindigkeit der Haftvermittler auf das Glas gesprüht wird. Dann läuft das Glas auf das lange Positionierungsband, dass einerseits als Puffer dient und gleichzeitig das Glas rechtwinklig in exakter XY-Richtung ausrichtet.

Die elektonische Steuerung der rund 20 Meter langen Produktionslinie nimmt Rücksicht auf das Format der jeweiligen Glasscheiben bei der Beflammung und beim Primen und überwacht mit Sensoren ihren Transport.

Fsdpfxev Ibmpj Aa Nefu

• LISEC production line is about 20 meters long

An entire production line consists of the cleaning, flame, primer and printing press as well as the respective conveyor belts between the stations.

• After cleaning, are placed on a mobile table, which is driven from the printer to the loading belt, where the glass is taken from the conveyor belt of the production line.

receives the print jobs from the prepress department and controls the transport through the flame and the primer. In the flame station, the glass is flame-flamed with an open flame in the continuous process. This improves the uniformity of the surface tension

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Đã đăng ký từ: 2019

Gửi yêu cầu

Điện thoại & Fax

+32 89 53... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Quảng cáo nhỏ

Maasmechelen

Maasmechelen

9.662 km

Bàn cắt kính

Bottero353BKM-J

Bottero353BKM-J

Quảng cáo nhỏ

Zamość

Zamość

8.467 km

Máy phay sao chép

RotoxZOR 941

RotoxZOR 941

Quảng cáo nhỏ

Mühlacker

Mühlacker

9.515 km

Dây chuyền sản xuất hoàn chỉnh

StürtzHSM-30/26 Compact+; 2MC

StürtzHSM-30/26 Compact+; 2MC

Quảng cáo nhỏ

HETEREN

HETEREN

9.625 km

Xe cẩu

Mercedes-BenzArocs 3251 AROCS 3251 8x2 FASSI F820RA.2.28

Mercedes-BenzArocs 3251 AROCS 3251 8x2 FASSI F820RA.2.28

Quảng cáo nhỏ

Maulbronn

Maulbronn

9.518 km

Trung tâm gia công thanh

elumatecSBZ 150

elumatecSBZ 150

Quảng cáo nhỏ

Lleida

Lleida

10.393 km

Cần cẩu nhẹ 500 kg

ABUS500kg 10 x 7 m

ABUS500kg 10 x 7 m

Quảng cáo nhỏ

Lleida

Lleida

10.393 km

Máy mài kính

LattuadaTLR 13 C

LattuadaTLR 13 C

Quảng cáo nhỏ

Groenlo

Groenlo

9.566 km

Telehandler

ManitouMT933 EASY 75D ST5 S1 Valid inspection, *Guarantee

ManitouMT933 EASY 75D ST5 S1 Valid inspection, *Guarantee

Quảng cáo nhỏ

Velžys

Velžys

8.346 km

Bàn nghiêng kính

TRIULZI-IGTilting table

TRIULZI-IGTilting table

Quảng cáo nhỏ

Concordia Sagittaria

Concordia Sagittaria

9.317 km

Cần trục công xôn xoay 360 °

AXA0135

AXA0135

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi