Máy chiết rót nước, dầu, xà phòng, AdBluePROTON EE-ELEKTRONIKA d.o.o

XFR1000

Máy chiết rót nước, dầu, xà phòng, AdBlue

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Năm sản xuất

2025

Tình trạng

Mới

Vị trí

Šašinovec

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

- Nhà sản xuất:

- PROTON EE-ELEKTRONIKA d.o.o

- Mô hình:

- XFR1000

- Năm sản xuất:

- 2025

- Tình trạng:

- mới

- Tính năng hoạt động:

- hoạt động hoàn toàn

Giá & Vị trí

- Vị trí:

- Krcevina 4, 10360 Soblinec, Hrvatska

Gọi điện

Chi tiết kỹ thuật

- Tổng chiều rộng:

- 2.400 mm

- Tổng chiều dài:

- 15.000 mm

- Tổng chiều cao:

- 2.800 mm

- Áp suất:

- 8 thanh

- Công suất:

- 10,9 kW (14,82 mã lực)

- Trọng lượng không tải:

- 6.400 kg

- Điện áp đầu vào:

- 400 V

- Trọng lượng nạp (tối thiểu):

- 200 g

- Khối lượng nạp (tối đa):

- 5.000 g

Chi tiết về đề nghị

- ID tin đăng:

- A17231422

- Cập nhật:

- lần cuối vào ngày 25.09.2025

Mô tả

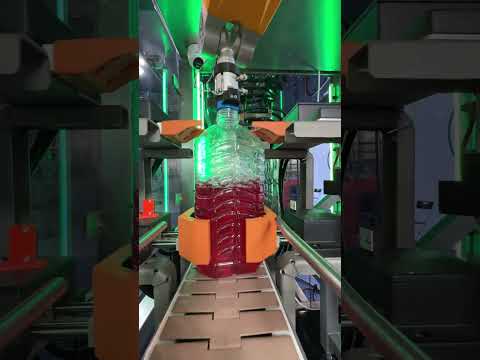

XFR 1000

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

Dujdpfx Asuq Nv Tea Nsn

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

Dujdpfx Asuq Nv Tea Nsn

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Đã đăng ký từ: 2020

Gửi yêu cầu

Điện thoại & Fax

+385 43 3... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Quảng cáo nhỏ

Mülsen

Mülsen

9.206 km

Báo chí container

PrestoHGS20

PrestoHGS20

Quảng cáo nhỏ

Kirchheimbolanden

Kirchheimbolanden

9.550 km

Hệ thống ghi nhãn cho hộp tròn và vuông

Weidmann Maschinen EtikettiermaschineFL-800

Weidmann Maschinen EtikettiermaschineFL-800

Quảng cáo nhỏ

Raszyn

Raszyn

8.609 km

Máy chiết rót tuýp, máy đóng tuýp

Jedlinski PackagingJTB-40

Jedlinski PackagingJTB-40

Quảng cáo nhỏ

London

London

10.018 km

Máy sản xuất đồ uống

GEACRAFT STAR 40/50HL BREWHOUSE

GEACRAFT STAR 40/50HL BREWHOUSE

Quảng cáo nhỏ

Kreuzau

Kreuzau

9.615 km

Cơ sở xử lý

FrymaMZM / VK 50

FrymaMZM / VK 50

Quảng cáo nhỏ

Schorfheide

Schorfheide

9.080 km

Trạm trộn cố định

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Quảng cáo nhỏ

Пловдив

Пловдив

8.445 km

Tháp xả cuộn thủ công Forstner

ForstnerMANUAL DECOILER TOWER

ForstnerMANUAL DECOILER TOWER

Quảng cáo nhỏ

Tata

Tata

8.866 km

Máy ép lệch tâm AIDA NC2-250, 250 tấn

AIDA NC1-250250ton

AIDA NC1-250250ton

Quảng cáo nhỏ

Niedźwiedź

Niedźwiedź

8.704 km

Đơn vị nén đơn vị ngưng tụ

BITZERHSK7461-80-40P

BITZERHSK7461-80-40P

Quảng cáo nhỏ

Fumane (Verona)

Fumane (Verona)

9.470 km

Phòng xi-rô

ALFA LAVAL

ALFA LAVAL

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi