Baler with pre-press flap LP 50 EH1Presona AB

LP 50 EH1

Baler with pre-press flap LP 50 EH1

Presona AB

LP 50 EH1

Năm sản xuất

2005

Tình trạng

Đã qua sử dụng

Vị trí

Hà Lan

Hình ảnh cho thấy

Hiển thị bản đồ

Thông tin về máy móc

- Nhà sản xuất:

- Presona AB

- Mô hình:

- LP 50 EH1

- Năm sản xuất:

- 2005

- Tình trạng:

- được tân trang tại xưởng (đã qua sử dụng)

- Tính năng hoạt động:

- hoạt động hoàn toàn

- Giờ vận hành:

- 30.408 h

Giá & Vị trí

- Vị trí:

- , Hà Lan

Gọi điện

Chi tiết kỹ thuật

- Lực ép:

- 50 t

- Chiều rộng cửa nạp:

- 1.100 mm

- Chiều dài lỗ nạp:

- 1.250 mm

- Chiều rộng kiện:

- 1.100 mm

- Chiều cao kiện:

- 720 mm

- Trọng lượng kiện:

- 550 kg

- Trọng lượng tổng cộng:

- 16.000 kg

- Dung tích bình dầu:

- 600 l

- Năm đại tu cuối cùng:

- 2024

Chi tiết về đề nghị

- ID tin đăng:

- A17766606

- Cập nhật:

- lần cuối vào ngày 20.06.2025

Mô tả

Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Cedpfx Asu Thhreayspw

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

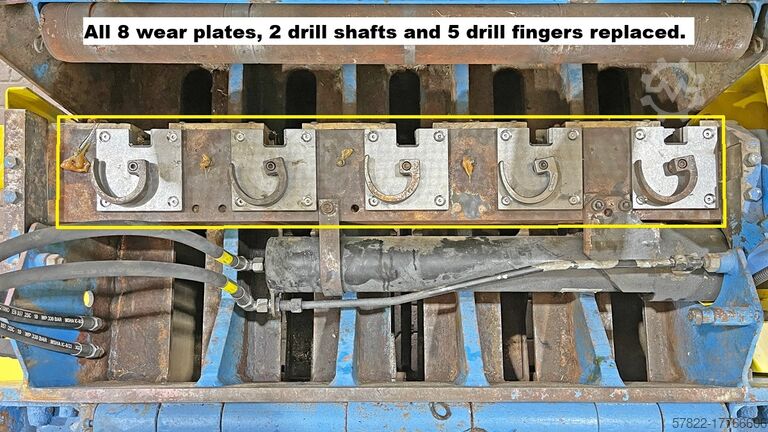

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Cedpfx Asu Thhreayspw

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Tài liệu

Nhà cung cấp

Lưu ý: Đăng ký miễn phí hoặc đăng nhập, để truy cập tất cả thông tin.

Gửi yêu cầu

Điện thoại & Fax

+31 597 2... quảng cáo

Những tin rao vặt này cũng có thể bạn quan tâm.

Quảng cáo nhỏ

Velbert

Velbert

9.558 km

Baler

Presona ABLP 80 VH1

Presona ABLP 80 VH1

Quảng cáo nhỏ

Kaufungen

Kaufungen

9.392 km

Đầu kéo tiêu chuẩn

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

Quảng cáo nhỏ

Fohnsdorf

Fohnsdorf

9.142 km

Máy ép phế liệu

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

Quảng cáo nhỏ

Karlholmsbruk

Karlholmsbruk

8.695 km

Chipper

Söderhamn Eriksson670-56

Söderhamn Eriksson670-56

Quảng cáo nhỏ

Zuzenhausen

Zuzenhausen

9.506 km

Máy hủy tài liệu

ZERMAZRS

ZERMAZRS

Quảng cáo nhỏ

Lagedi

Lagedi

8.300 km

Bình đựng báo chí

HusmannSPB 20 SEN-E

HusmannSPB 20 SEN-E

Quảng cáo nhỏ

Thisted

Thisted

9.279 km

THÙNG KEM 10.000L

APV

APV

Quảng cáo nhỏ

Sinsheim

Sinsheim

9.502 km

Máy tạo hạt

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

Quảng cáo nhỏ

De Rijp

De Rijp

9.662 km

Thùng ép

HusmannSPB 22 SEN-E

HusmannSPB 22 SEN-E

Quảng cáo nhỏ

Tata

Tata

8.866 km

Máy ép kiện Pal Pacomat V 50t

PAAL PACOMAT V50ton 500kg bale

PAAL PACOMAT V50ton 500kg bale

Quảng cáo của bạn đã được xóa thành công

Đã xảy ra lỗi